- +27 79 866 5061

solutions@resatech.co.za

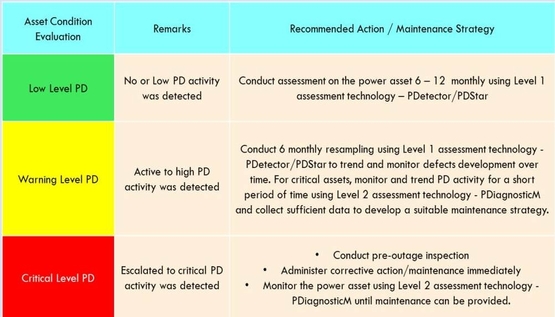

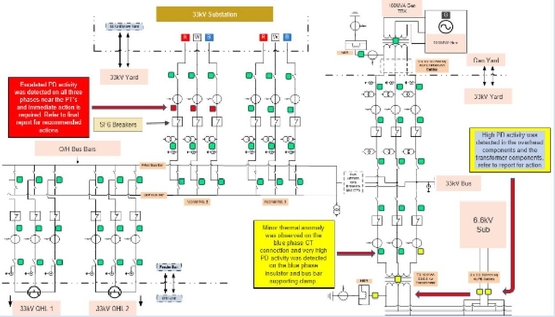

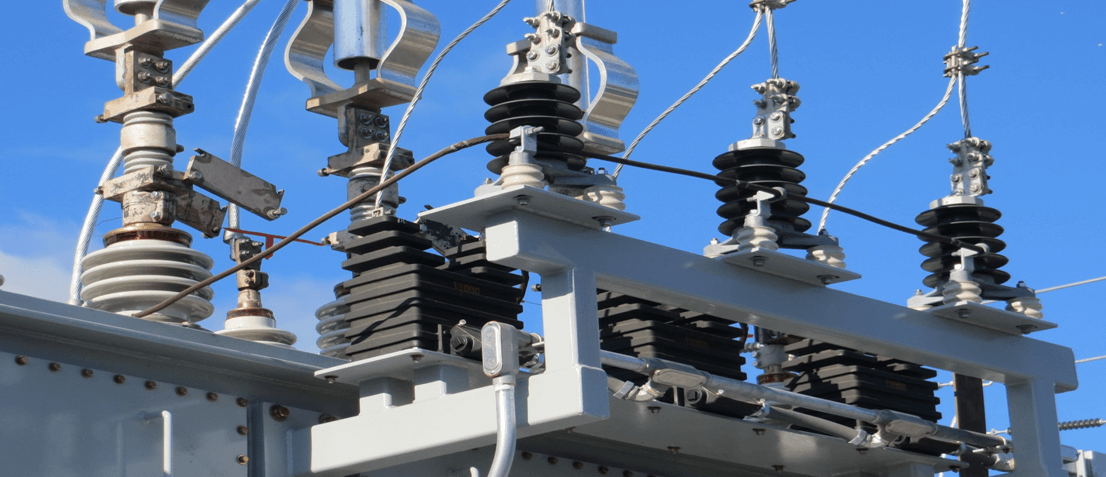

This is a routine inspection conducted with our tier 1 assessment technologies, PDetector or PDStar utilizing the maximum number of sensors applicable to the MV or HV equipment under test. The assessment will confirm if there is any PD activity on your substation equipment and power assets. Once data is collected and analysed, a report will be provided with any abnormalities given and if PD is found, maintenance suggestions will also be provided. Our tier 1 PD assessment technologies can detect and analyse almost 95% of MV and HV insulation defects in the field.

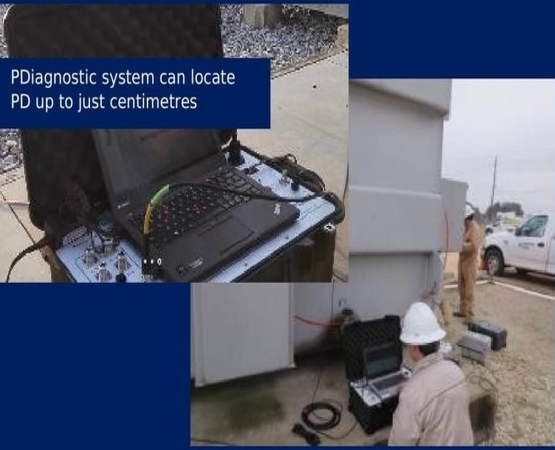

If PD is already a known issue, we offer a location service where our technicians will utilize our accurate location solutions to locate the PD signal source, whether it is internal or external of the power asset. At this stage, a more advanced PD diagnostic and locating system, the PDiagnostic, is used. This system employs an array of sensors configured in a particular order, guided by the type of MV or HV equipment under test. Once data is collected and analysed, a report will be provided with any abnormalities given and if PD is found and located, maintenance suggestions will also be provided. This method is sufficient to locate known PD in the power network and very seldom will the Level 3 PDExpert service be required.

The PDExpert is PMDT's third level of Partial Discharge (PD) Expert Diagnostic and Location System. It is a powerful, portable, multi-channel system of impeccable design used to analyse and pinpoint PD signals coming from a power asset within centimetres while the power system is energized. The system consists of UHF, AE, HFCT and ultrasonic sensors, one advanced UHF/PD signal processing unit, one oscilloscope, filters, and other accessories. The system employs ultra-high speed data acquisition and advanced digital signal processing technologies, compares the UHF, AE and HFCT signals of different frequency ranges to determine if it is PD or noise, and locates the source in power assets accurately by utilizing Acoustic-Electromagnetic Combination Location Technique, time Difference of Signals' Arrivals (TDOA), and 3D Positioning Technology.

Our Level 2 PDignostic System is Capable of detecting and locating known PD in the power network. Level 3 PDExpert Service may only be employed in exceptional circumstances.

• The assessment requires no outage – it does not interrupt normal operations.

• It is a predictive assessment – failures can be prevented.

• The test is non-destructive and non-intrusive – no damage to electrical equipment.

• Historical trending is possible – current and previous data can be compared to evaluate the development of the defects.

• High resistance connections can be identified and rectified before they fail.

• It is a tool for condition-based maintenance – assets are assigned failure risk levels based on their condition.

• Planning and financial control – time to schedule repairs can be managed and repairs can be budgeted for.

• Improve safety of equipment and personnel.

• Reduction in high cost of insurance and penalties.