- +27 79 866 5061

- pitso.masooa@resatech.co.za

Superior Handheld Partial Discharge Detector for Electric Power Equipment with Thermal Imaging Camera, 100 MSPS HFCT Testing, A 4.3" Touch Screen, Multi-Sensor and Cloud Diagnostic Technology, 3G/4G/WI-FI Communication, and Data Management Software.

PMDT is proud to present one of their latest innovations, the PDStar. It integrates On-Line Partial Discharge (OLPD) testing and Infrared testing for MV and HV equipment, which combines UHF, AE, Ultrasonic, HFCT, TEV, and Infrared testing technologies. It is applicable for online PD testing, as well as abnormal heating and defect detection on all types of substation equipment. PD amplitude, PRPD, PRPS, and infrared spectrums provide critical data for determining the operational condition of electric power equipment. It connects to the PMDTCloud via Wi-Fi/3G/4G to upload test data, download test tasks, and receive diagnostic results in real time. Another uniquely advanced feature of the PDStar is that it integrates with a 100 MSPS (Mega-Samples per Second) HFCT signal processor, which greatly improves the performance for power cable OLPD testing.

For substation operators, conducting OLPD testing on power cables has always been a challenge due to the dangerous aspects involving the close proximity to the online equipment the tester would have to be in order to perform the testing efficiently and accurately. The PMDT’s PDStar provides an advanced solution for this issue.

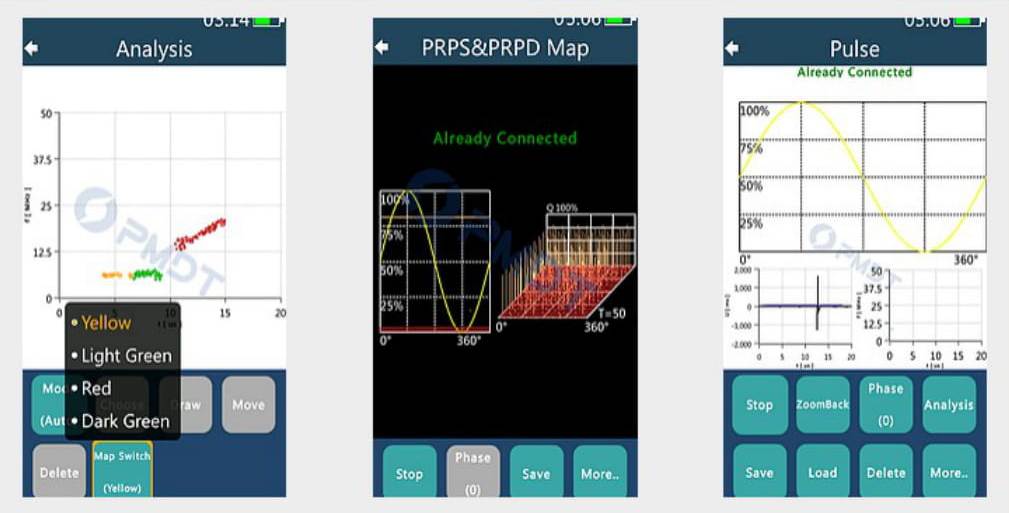

The PDStar features the superior Cluster Analysis (CA) function with a 100 MSPS HFCT Signal Processor that enables the user to conduct advanced OLPD testing and diagnostics on power cables. The PDSS (Partial Discharge Signals Separation) technology is employed to separate noise from PD signals, and to separate different types of PD signals into different groups. Waveforms, PRPD & PRPS, and pulse spectrums are provided for data analysis to determine the PD type.

Thus far, infrared testing and OLPD testing have been important but independent for condition-based maintenance programs of power equipment. Substation operators have been conducting the two routine testing methods separately for many years. The PMDT’s new innovative PDStar now makes it possible to test PD and IR together in one single tool, which allows for a more productive, efficient, and cost-effective online testing and maintenance program for customers.

The PDStar's Thermal Imaging Camera is convenient to use by simply attaching the Thermal Imaging Camera to the PDStar main unit. It has high resolution and can detect any abnormal heating and defects effectively.