- +27 79 866 5061

solutions@resatech.co.za

Partial discharge testing is the leading methodology for assessment of the insulation system in medium voltage substation components. Although the test is reliable and effective, trends show that major failures are still encountered even where regular assessments are customary. Failure root cause analysis is often complex due to inadequate operational data as well as the catastrophic nature of many MV failure mechanisms. One of the main reasons for this is that where assessments are conducted regularly, the typical assessment interval is 12 to 18 months for non-critical assets, which is a fairly long time if sufficient operational data is required to support realistic failure

analysis. Tapering assessment interval to between 3 to 6 months may partially address the issue but will unfortunately introduce a new financial burden, owing to the increased frequency of assessments. Secondly, from a safety perspective, field personnel will more often be in proximity to energised substation components since online PD testing is conducted on live equipment, which will add another undesirable dimension to OLPD testing safety conundrum. One of the most common topics during pre-job risk assessment when conducting OLPD testing, is the safety of personnel in the unlikely event of component failure while the assessment team is inside the test area. The most appropriate risk mitigation intervention is the use of arc flash suits and phase shields while inside the test area which may be the substation or the cable basement, but this has proven to be highly impractical as it limits the individual’s agility, mobility and access to test points in rather tight spaces, and lastly it makes control of assessment instruments impossible. This often ends up being ruled out completely, even though the consequences will be calamitous should the unthinkable happen.

Permanent online substation monitoring is indisputably the ultimate solution if safety of personnel and equipment as well as reliability are to be adequately addressed, however the cost of such a system is the very reason modern power plant owners hardly ever discuss the possibility of taking that route. An ideal solution is therefore one where personnel and equipment safety, reliability, and the overall service costs are equally addressed without compromising the system’s efficiency and the ultimate quality of service.

This adds another positive dimension to medium voltage power plant condition-based maintenance by remotely monitoring the activity of selected parameters on MV power assets and setting different alarm thresholds with added advantage of fast and effective status communication. This approach is however not entirely impermeable in that for some MV assets, the monitoring principle is based on the maximum amplitude of targeted parameters with no actual data analytics employed.

One of its multiple drawbacks is that if abnormal levels are observed, an assessment team has to be dispatched to site with diagnostic equipment to acquire actual data for further analysis before an erudite judgment on the condition of the MV asset is passed. This adds additional costs and contributes to OLPD testing risk factors where personnel find themselves in proximity of energised substation components yet again. Another major drawback of this technique is that detrimental insulation defects are not addressed at incipient stage as they are not noticed and appear “low and not concerning” but attract attention once they have progressed to abnormal levels.

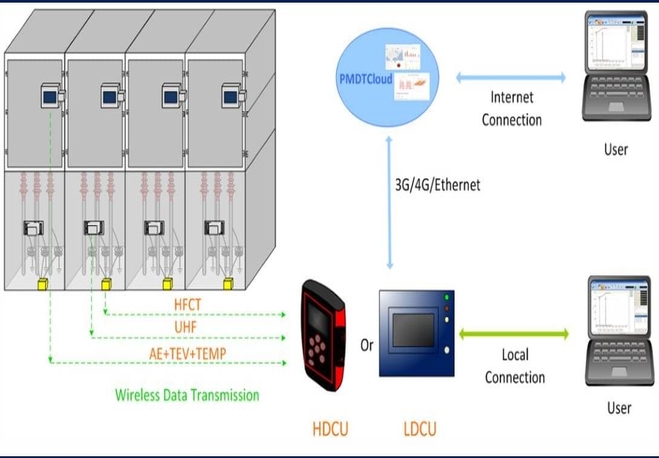

Our autonomous online partial discharge testing methodology, using the PMDTiSmart technologyis the safest most effective way of online partial discharge testing and completely addresses the above stated challenges. The system entails installation of smart, wireless partial discharge sensors in each switchgear cubicle and one local data collecting unit (LDCU) which at predetermined intervals autonomously collects real partial discharge data from each sensor and uploads it to the PMDTCloud for automatic analysis and instant report generation.

The sensors’ measuring cycle can be configured from 6 to 10 000 minutes however, recommended data sampling interval is 24Hrs for envisaged 7 years of sensor battery life. This innovative MV substation condition based maintenance system provides power plant owners with a rare fusion of safety, reliability, exceptional service quality and affordability which is further heightened by our added remote monitoring and patrol service consisting of weekly and monthly reports, data management as well as assets condition re-evaluation in support of cloud diagnosis. This is a cost effective, airtight system with the benefits of a permanent online substation monitoring scheme.

- No field Technicians taking data on regular basis in the energised substation

- The risk associated with OLPD testing is eliminated completely, 100% risk reduction

- Diagnosis is based on the actual PD data and is automatic, immediate, and conclusive

- No need to dispatch personnel to site to acquire actual PD data for further scrutiny

- Developing defects are identified at inception stage

- Maintenance interventions can be administered in time at lower cost

- PD type determination automatically performed by the intelligent cloud server

- Cloud diagnostics with deep learning technology

- Diagnostic results are sent with detected signal details

- Real PD data collected and analysed 365 days a year

- More meaningful trends and adequate data for failure root cause analysis

- Reduction in untimely failures due to availability of real trending data and early identification of defects

- Multiple statistics charts

- Devise status evaluation details

- Normal and abnormal trends analysis

- Status reporting on web-enabled devices: Normal – Warning - Alarm

• No Need for Time-Consuming Work Permits

- No frequent visits to site for testing, no tedious paper-work necessary

• Less Contractors Roaming Site

- No frequent visits to site for testing, less contractors on site

- No contractors testing in substations – reduction in exposure to risk

• Cost Effective

- The system is cost-effective compared to permanent online monitoring but has the benefits of POLM