- +27 79 866 5061

- pitso.masooa@resatech.co.za

A Partial Discharge Sensor is used to separate the high frequency partial discharge signal from the line voltage and is in general a high pass filter in a frequency range several ten kilohertz up to several ten megahertz. Typically, so called coupling capacitors are used, but other high frequency sensors such as high frequency current transformers or antennas are available on the market. Whatever sensor is chosen, it must meet the requirements specified by the international standard and it must provide the partial discharge high frequency signal in a frequency range with the right coverage of the test object.

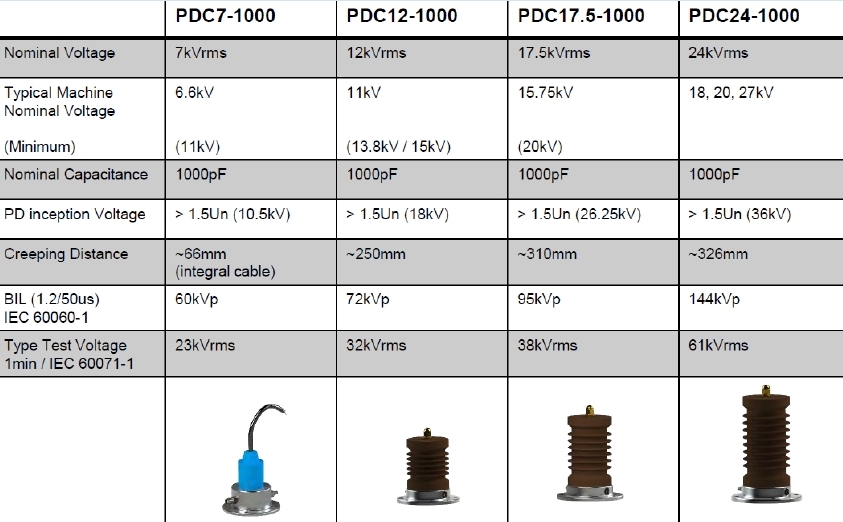

Coupling Capacitors are the most common used sensors to measure partial discharges in rotating machines. They consist of a high voltage capacitor and a measuring impedance. The capacitor and the measuring impedance together define the frequency range of the sensor. Our coupling capacitors are designed for heavy industrial environment and meet internationalstandards such as creeping distances, impulse lightning and over voltage withstand.

Our coupling capacitors have their quadrupole built-in at the bottom including over voltage protection for the instrument and personnel safety. The quadrupoles are designed for a frequency range from several tens of kilohertz up to several hundred megahertz. The special designed quadrupole provides additionally the line

frequency in a scale of 1:2000 to the applied line voltage, allowing to synchronise the partial discharge detector with the same signal cable. The virtual grounded signal output protects the signal cables from eddy currents due to high magnetic fields in the testing environment. For very large rotating machine monitoring, it is recommended to use the standard capacitance of 1000pF but for customers requiring 80pF coupling capacitors these models are also available.

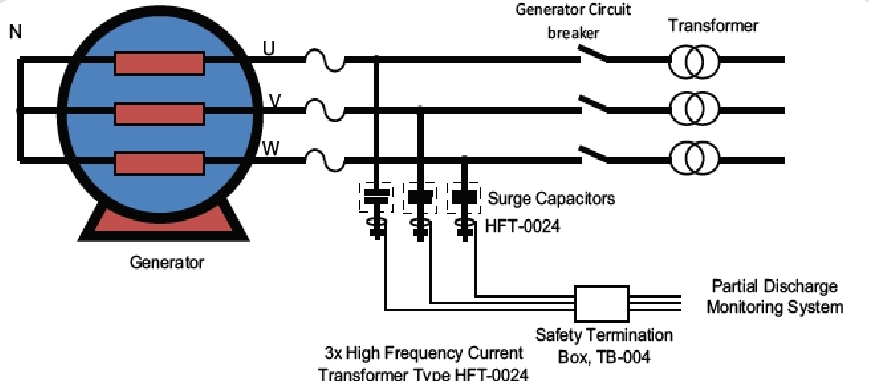

Large industrial motors in the 6.6kV range often have a small high voltage termination box, which do not provide enough space to install coupling capacitors. For such applications, high frequency current transformers canbe used in conjunction with the already installed surge capacitors or directly on the ground lead of the high voltage cable to measure the partial discharge activity of the machine. Our PD instruments are compatible with HFCT’s and allow full PD diagnosis using these types of sensors.

High Frequency Current Transformer (500KHz - 50MHz) - When PD occurs, there are small current pulses that are induced onto the ground shield or case ground. These pulses will travel dozens of meters along the ground grid in the form of high frequency current pulses in the range from 500kHz to 50MHz, usually centred near 10MHz. High Frequency Current Transformers are a reliable method to measure these high frequency PD pulses. These pulses spread out onto the ground grid like ripples in the water. They are especially useful for quickly testing for internal PD in a large area such as an entire power transformer or an entire cable, or even an entire substation.

The HFCT sensor with a split core can be easily clamped around a low resistance grounding lead. HFCT sensors have a distinct advantage of being able to detect PD signals on cables from long distances up to 1km away (this limit depends on the type of ground shield and the strength of the PD pulse). This means multiple PD signals and noise signals can also be detected from many points on the ground grid where a ground lead is exposed.

Large motors and generators are typically equipped with surge capacitorsto protect the machine winding. Installing a coupling capacitor directly next to the surge capacitor would significantly reduce the measurement sensitivity. In this case, the surge capacitors can be used to measure partial discharges by adding a high frequency current transformer on the ground lead. For this type of installation, the installation of the surge capacitor must be slightly modified, by insulating the body of the surge capacitor to ensure all the signal passes through the high frequency current transformer. As the grounding wire section varies from different diameters, different models of the high frequency current transformers are available. We offer complete installation kits including fiberglass insulation sheet and bolts, cables etc.

As RTD’s are nearly installed in every machine, they can be used as additional sensors. Since the RTD’s only cover a small portion of the machine winding, just around the RTD itself, it is only recommended to use them as an addition to the coupling capacitors or High frequency current transformers. Obviously, it is recommended to use only the RTD’s located at the high voltage part of the winding. The TMS-9006 RTD module couples the high frequency signals out of the RTD signal cables. As the coupling is done via high frequency current transformers, even used RTD’s can be used, without influencing the temperature measurement. Additionally, the built-in LP Filter reduces the noise of the RTD signal.

Partial Discharge measurement requires a proper grounding of the signal cables between the sensor and the acquisition system and must provide a safe and secure connection interface for the operators. We offer the TB-004 safety termination box made of stainless steel and provides IP66 protection and is suitable for indoor and outdoor installation. Alternatively, smaller termination boxes such as the TBS-003 and TBS-004 are available offering the same protection rating but have their BNC terminals externally connected. We generally sell the sensors as complete sets including all necessary parts for installation such as screws, bolts, nuts, HV cables, safety termination box, signal cables (typically RG58 c/u) and the suitable BNC connectors.