- +27 79 866 5061

solutions@resatech.co.za

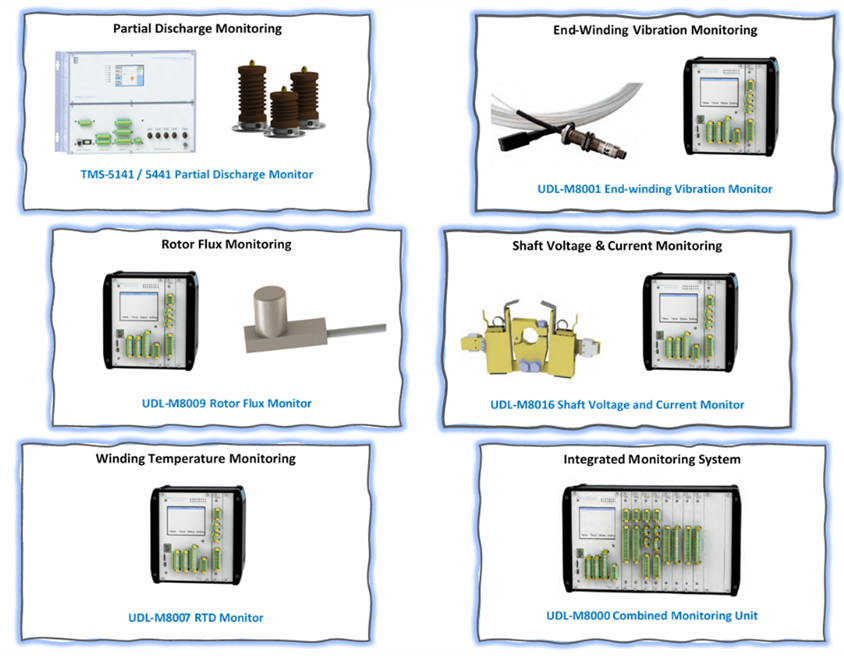

Early fault detection is critical in avoiding major component failure and unplanned downtime. Resatech supplies and installs sensors, monitoring instruments, acquisition systems and diagnostic tools to reveal the actual condition of your Turbo Generator. We offer different monitoring options that you can select from:

• Partial discharge

• End-winding vibration monitoring

• Rotorflux monitoring

• Shaft voltage and current as well as stator winding temperature monitoring

Turbine generators are among the most complex and expensive items in the modern power plant. High costs of repairs and replacement and the exorbitant loss of revenue in the unlikely event of failure make early detection of generator defects highly imperative. Monitoring critical aspects of your generator can prevent a major catastrophe and improve equipment reliability. Our solutions provide plant operators with a centralized, holistic view of the Turbo Generator and its major components by visually overlaying key data gathered by any or all of the above monitoring options onto a single graphical representation of your generator.

This allows you to monitor the entire Generator and its electrical components on one screen. This information is key in supporting early fault detection and reliably informs maintenance planning over the machine’s life cycle as it ages. Machine manufacturers and plant operators are provided with vital information during site acceptance phase of new and refurbished machines. This greatly reduces the risk of failure and unplanned downtime.