- +27 79 866 5061

- pitso.masooa@resatech.co.za

• MV and HV Switchgears, transformers, rotating machines, power cables, outdoor substations, switchyard components and accessories play a pivotal role in the overall operation of the modern power plant.

• Reliability of these assets is key to the successful operation of the plant.

• Regular assessments and condition monitoring should form an integral part of their maintenance strategy.

• Failure is often accompanied by devastating outcomes from safety and financial viewpoints.

• Online condition assessment is the most reliable method of revealing incipient faults in power plant systems.

• Predicting failures is now possible through Partial Discharge testing and analysis.

• Once the condition is known, preventive counter measures can be administered in time to avert potential catastrophe.

• The assessment requires no outage and does not interrupt normal plant operation

• Data is collected from live MV assets using an array of sensors

• Sensors are placed at strategic locations on the MV asset under test to obtain the best signals possible

• The assessment is non-intrusive and non-destructive

• Data is analysed using cutting-edge analysis software and latest techniques in PD technology and the assets’ failure risk levels are determined

• Each PD detection method has limitations

• Using multiple sensors provides a wider PD coverage spectrum

• Multi sensor testing strategy offers better noise recognition and discrimination

• It allows for a more realistic and accurate status diagnosise

• Various PD activities are known for their unique frequency bandwidths and distinctive patterns

• Our different PD detection methods are characterized by their unique frequency ranges, ensuring that PD activity is always discovered, located, and characterized

• It is a predictive assessment – failures can be prevented.

• Historical trending is possible – current and previous data can be compared to evaluate defects development over time.

• Incipient faults such as high resistance connections and other forms of insulation degradation can be identified and rectified before costly equipment failure.

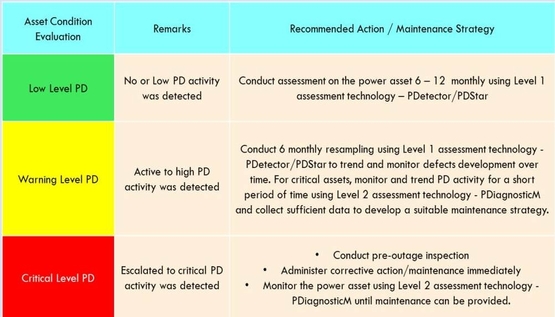

• It is a tool for condition-based maintenance – assets are assigned failure risk levels based on their condition.

• Planning and financial control – time to schedule repairs can be managed and repairs can be budgeted for.

• Improved safety of equipment and personnel.

• Improved asset reliability, better risk mitigation strategy, low maintenance costs and fewer unplanned outages

• Reduction in high cost of insurance and penalties in regulated markets.

• The type of PD present

• The location of the discharge

• The magnitude and repetition of the discharge pulses

• The type of MV asset under test